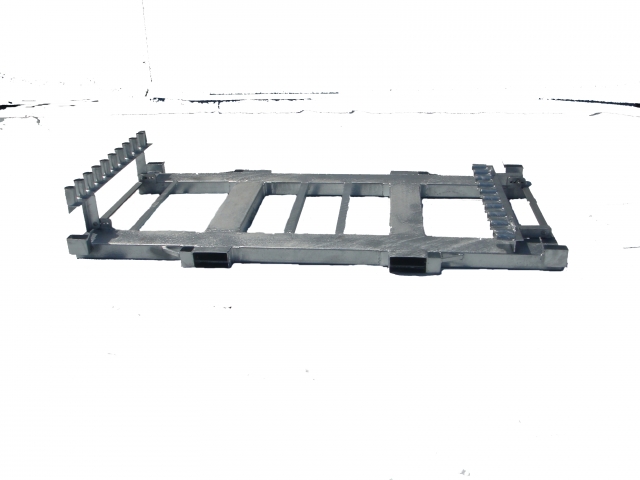

Products: Composite pallets

New composite pallet, mulitfunktionale the system of guardrail, and footplates K1, all on one pallet, high cost and time savings by alternating removal of guardrails and footplates K1

The multifunctional system of guardrail, and footplates.

Everything on a pallet!

High cost and time savings by alternating removal of guardrails and footplates!

Protected by patent

Patent WO 2009/138071 A1 + 2010/028624 A1

Publication CN 301376560 S

Design Patent EM001662768 0001 + 002

The unique new composite pallet KPA 22 M is suitable for safety barriers, which made of plastic or steel.

Footplates K1, K1 Multi footplates,

Hoarding and compensation elements and enclosed fence elements.

The multifunctional system!

Length 2.22 x 1.14

galvanized

Empty weight 100 kg

1 Pallet for 3 systems

This multifunctional system allows the use of the pallets for guardrail, hoarding compensation elements and enclosed fence elements, by using other arms. Every 20 and 22 units can be stacked on a pallet. Different holes for 3 products, forklifts and shoe storage area can be put on a ground.

In the multi-composite pallet KP 22 M - K + L - on the pallet not only 20 guardrail and 26 multi footplates K 1, but also 10 multi-stacked reversible beacons. These can be transported without any scratches or damage.

When a construction site is equipped with the new multi-composite pallet KP 22 M - K + L - with 20 multi-guardrails, 26 multi-footplates K 1 and 10 multi-reversible beacons, you have the solution to every shut task ready!

All unnecessary components and shut materials will be stacked safely and tidy on the new multi-composite pallet KP 22 M - K + L -.

With the new multi-composite pallet KP 22 M - K + L - with short and long arm the order on the site will be a breeze!

Advantages of Combined palettes, which pay off for you as a user!

1. Almost all barriers and footplates from different manufacturers can be loaded each another on a composite pallet

2. Alternating removal of guardrail, even from a truck, is possible

3. The truck can go along for unloading and loading at the building line

4. Thereby the assembly of the construction fences and barriers could be accelerated

5. The full composite pallet can be easily combined using a forklift longitudinal and lateral driving

6. The stacker fork is inserted into the profile. Then slipping the composite pallet truck prevented from actively

7. Guardrail made of plastic or steel. Footplates K 1, K 1 and Multi footplate compensating elements and closed hoarding elements can be arranged at the same time on a single pallet

8. Through the intelligent arrangement of the composite pallet (feet under fences) results in a low center of gravity and a low overall height. The composite pallet is quiet simple mobile and saving space.

9. The full composite pallet is double stacked in storage (no bearing rails included)

10. Quick to be assembled, as all materials can be taken as needed

11. The barrier can be built in the reverse process, which requires less space

12. No loss of footplates of the composite pallet. Not even during filling and construction in the field

13. The holder of the empty pallet can be folded down. This enables a low height of open transport and prevents dirtying of the holder openings

14. Large water holes avoid freezing of the shut elements

15. No freezing of the footplates, as they are stored on lands

16. The transport with hand pallet truck is also possible through the use of special equipment

17. With the removal of the first shut-off, the previously backed footplates for building accessible

18. No additional assurance of the feet through a network

The composite pallet